High-standard maritime cooling & propulsion

Discover our solutions

Keep

Moving

Forward

We have earned an excellent reputation when it comes to supporting our clients with outstanding cooling and propulsion solutions. We are not easily satisfied and go to great lengths to provide our clients with a solution that is as optimized and reliable as possible. Using all our expertise, craftmanship, high-quality machinery and the timeless effort of our dedicated employees. So, we redefined our mission: Blokland - Keep moving forward.

Our storyThe best solution for your application

Based in the Netherlands and with roots dating back to 1962, Blokland Non Ferro has set a new standard in terms of craftmanship, engineering and construction.

Our high-standard cooling and propulsion solutions are installed in many commercial shipping, pleasure crafts and industrial applications worldwide.

Cooling

Innovative cooling products for main engines, auxiliary engines and generator sets.

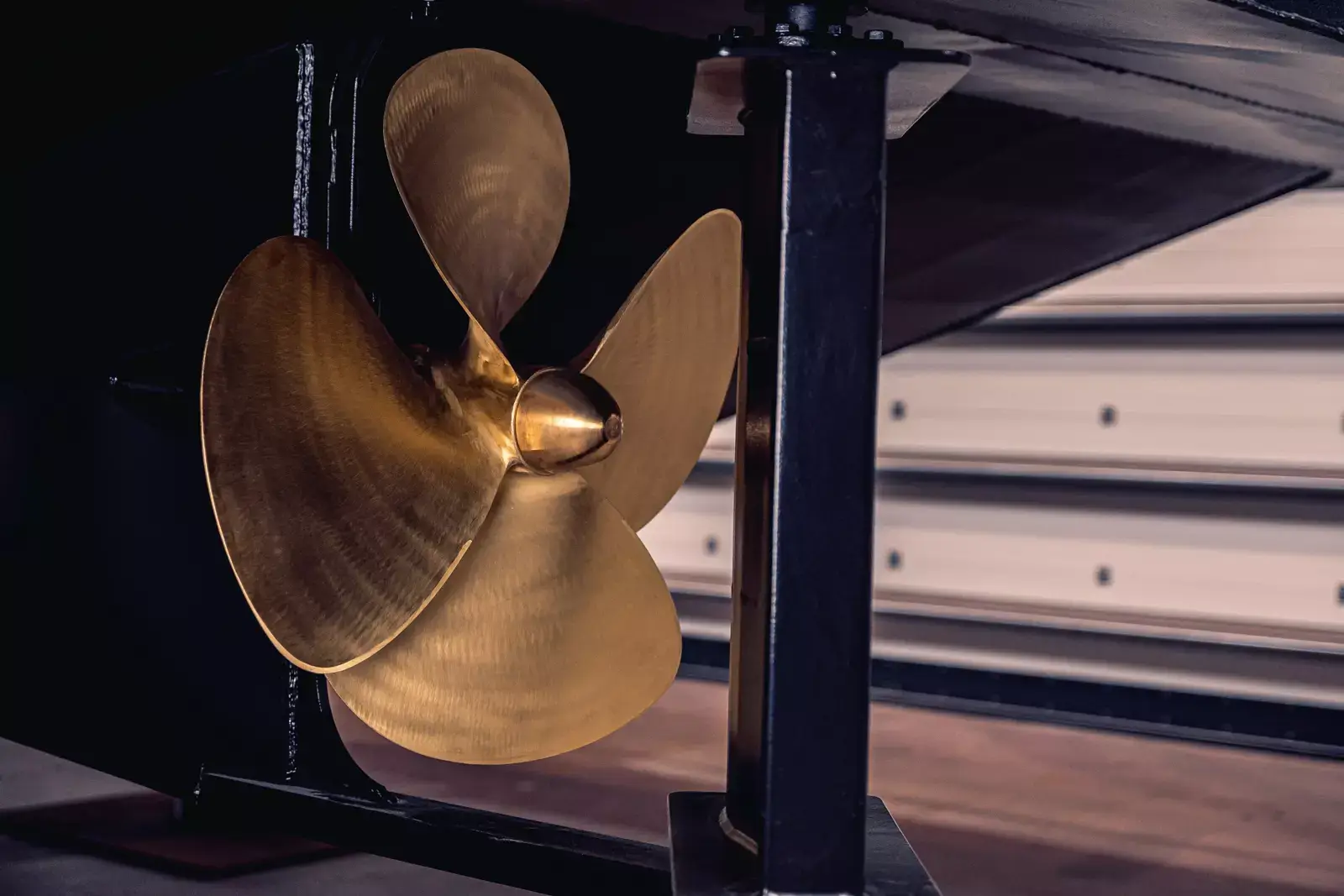

Cooling solutionsPropulsion

Outstanding propulsion solutions for commercial vessels and pleasure crafts.

Propulsion solutionsGlobal deployment

Blokland is worldwide involved in maritime cooling and propulsion solutions, as well as service and additional applications for industries.

Find an agent

Please contact our sales department.